While marketing, merchandising, and buying take the center stage when one talks about retail planning and operations, what gets relatively less attention is the store replenishment process.

How effectively you manage your store replenishment ultimately decides whether the product reaches the customer when she needs it. According to an estimate, it costs retailers over $1 trillion in lost sales due to stockouts. Between 70 and 90% of stockouts are caused by poor shelf replenishment practices.

On the contrary, high inventory causes excessive inventory obsolescence, pilferage, and higher expenditure on maintenance, insurance, and taxes. The annual additional cost of holding excess inventory can be as high as 32%. In addition, excess inventory leads to margin erosion and increasing advertising costs.

As you might have guessed, no retailer can afford to ignore store replenishment processes as it has a major impact on profitability and sales.

Building an effective and accurate store replenishment process improves sales and reduces store and supply chain costs.

Here are the top 5 reasons why your store replenishment might be ineffective.

- You Rely on Static Long-term Demand Planning

For a large part of the retail era, demand planning based on historical data and human expertise has proven to be very effective. However, in today’s era, the demand complexities have increased manifold leading to elevated levels of

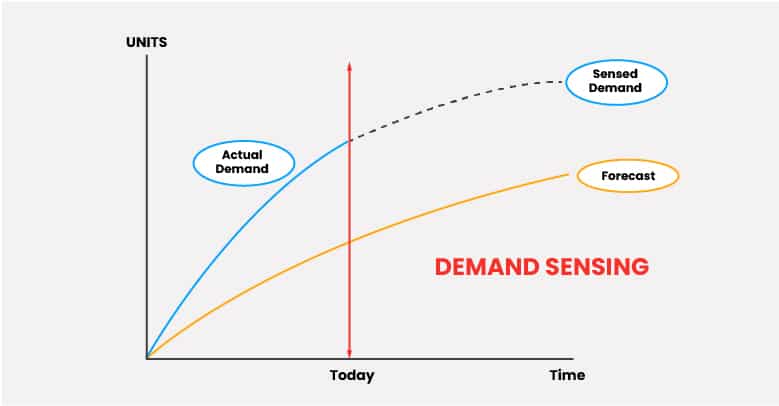

forecasting errors. A major cause of this is the static one time forecasting framework that many retailers still use.One of the best forecasting practices today is to build separate long-term demand planning and short-term demand sensing capabilities.

Demand sensing uses a range of dynamic demand predictors to forecast in the near term. It includes exogenous factors such as weather, temperature, holidays, etc. as well as internal factors such as promotions, pricing, inventory,

etc. It usually uses ML-based algorithms to predict real-time demand. One such solution is Algonomy’s Forecast Right.Although demand sensing and planning have different purposes, their relationship needs to be dynamic. For example, demand sensing capabilities can help you know well in advance when your long-term forecast is erroneous and

accordingly offset it. Such an activity performed over time reduces the overall forecasting error and could potentially help you maintain high availability while reducing costs.

Demand forecasts can be course-corrected based on actual demand with demand sensing capabilities

- You Treat Every Channel-Category-Store Combination the Same

Trends such as omnichannel, price, and convenience sensitive consumers and short product lifecycle have completely disrupted the retail scene. Today, every store, every channel, and every category behaves differently. One of the

biggest mistakes that retailers make is treating them the same. This often leads to inconsistent experience for customers across channels and stores.For example, even though your store might have enough supplies, an out-of-stock message on your site can put a serious damper on customer experience and may even result in lost sales.

In fact, there’s a 91% chance dissatisfied customers won’t do business with your brand again. Therefore, your replenishment strategy should consider these nuances to be effective.

- You Don’t Systemically Adapt to What Is Happening on the Shelf

Ask any store manager and they would tell you that what happens on the shelf ultimately decides store success. Nothing is more excruciating for a customer than to see empty shelves. One of the main reasons why it happens is because

of the dynamic effects that play in your store.For example, a promotion for one product can lead to decreased (Cannibalisation) or increased sales (Halo effect) for other products. Promotions is just one aspect. There are several more such as product placement, visual

merchandising, pricing, new product launch, and more.While your store managers are smart to figure out some of them, they might not have the bandwidth to keep a tab on these effects every time they happen. Hence, what is needed is a systemic approach to identifying these effects and

course correcting in your replenishment plans.

- Your Replenishment and Inventory Planning Is Not Optimized for Constraints (and Cost)

Planning is just half of the puzzle, the other half is the execution! As any learned and experienced supply chain expert would tell you, it’s all about the theory of constraints and most importantly economics.

Even if your replenishment planning is very accurately mapped to demand, it needs to be optimized for supply chain factors such as lead time, minimum order quantity, shelf life, expiration date, etc. This not only helps you meet

store demand but also reduce costs such as shipping and handling costs, inventory costs, ordering cost, shrinkage, etc.Increasingly, retailers want to automate this process because of the complexities involved and the manual calculations required to get it right.

- Your Supplier Collaboration Is Fragmented and Inefficient

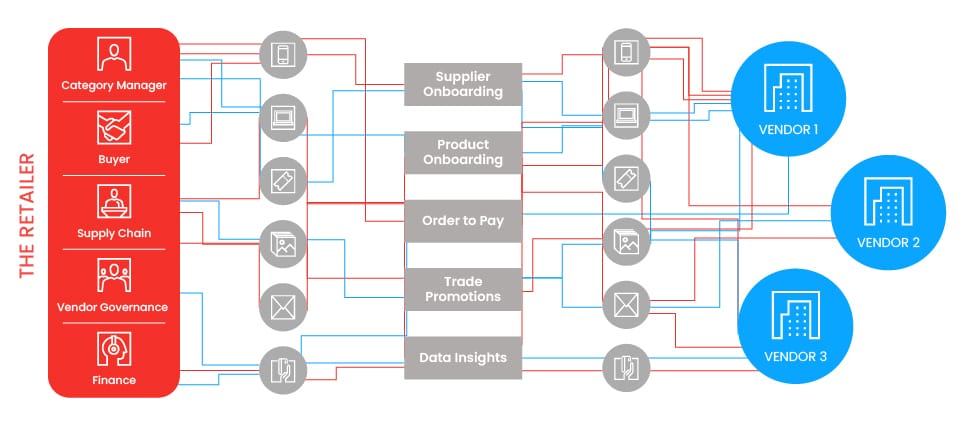

According to research, about 10-30% of stock outs happen due to supplier shortages. One of the major reasons why it happens is because of lack of transparency and collaboration between retailer and vendor.

Most retailers would agree that their vendor processes are fragmented and operate in silos. Every stakeholder on the retail team interacts with vendor stakeholders through a messy net of communication channels (see below).

What this results in is a lack of collaborative planning and mutual trust leading to low fulfillment rate, longer lead times, and vendor dissatisfaction.

Most retail firms have realized this gap and are proactively working to create a unified platform similar to Vendor Link that would

integrate all vendor processes and enable seamless data sharing for better outcomes.In fact, retailers who improved their supplier collaboration cited a 20% increase in revenue.

Fragmented vendor collaboration and data sharing

1-click Intelligent Replenishment

Retail companies, especially with a large number of SKUs, need to relook at their replenishment strategy. One of the most effective ways of achieving accurate, efficient, and cost-effective replenishment is with the help of a demand-driven and business operations tailored system.

However, given the breadth and depth of categories that need to be managed, and supply chain complexities in today’s era, manual ordering has become very inefficient and expensive.

Therefore, there is a need for “a layer of super-human intelligence on top of existing ERP systems that optimizes store replenishment to account for complex demand patterns, while reducing supply chain costs and markdowns”. One such solution is Algonomy’s Order Right.

Order Right builds a layer of Artificial intelligence on top of your existing planning tool and optimizes your store replenishment by making smart ordering suggestions to reduce out of stock, improve margins, and cut down wastage.

It uses a library of ML-based algorithms curated specifically for retail scenarios to accurately predict demand at store, channel, and category level, and optimize orders to achieve category objectives and reduce supply chain costs.

Download Order Right Brochure here or schedule a demo.